The Evolution of Automation: A Journey Through Time

From Simple Machines to Smart Systems

Automation has undergone a remarkable transformation over the centuries, evolving from rudimentary tools and simple machines to sophisticated smart systems that govern our contemporary environments. The earliest instances of automation emerged during the Industrial Revolution, when mechanization began to enhance productivity and reduce labor costs. Early inventions, such as the water wheel and the steam engine, laid the groundwork for automated processes, establishing a paradigm shift in manufacturing. As society advanced, the development of electronics and computer technology introduced a new era of automation. The 20th century witnessed a surge in production-line automation, improving efficiency in factories and setting the stage for increased mass production. However, the true leap toward intelligent automation occurred with the advent of digital technology, enabling the integration of complex algorithms and data analytics into machinery. As we progressed into the 21st century, the emergence of the Internet of Things (IoT) revolutionized automation once again. With machines capable of communicating with each other and sharing data in real-time, systems could become self-regulating and adaptable. This shift towards smart automation not only refined operational efficiency but also allowed for real-time monitoring and control across various sectors, significantly enhancing the speed of innovation and fostering intelligent decision-making.

Key Innovations That Shaped Automation

The path to modern automation is marked by several key innovations that have dramatically influenced how industries operate. One of the most significant developments was the integration of control systems, specifically Programmable Logic Controllers (PLCs) in the late 1960s. The PLC allowed for programmable control of machinery, providing the flexibility to change operations without the need for extensive rewiring. This innovation paved the way for greater automation in manufacturing processes. Another critical innovation was the introduction of robotics in the 1980s, where mechanized arms began to take over repetitive tasks, driving efficiency and accuracy in manufacturing. Robots enhanced productivity in industries from automotive to electronics, and their evolution has now led to collaborative robots (cobots), designed to work alongside human operators safely. More recently, advancements in machine learning and artificial intelligence have provided unparalleled opportunities for automation. These technologies enable systems to learn from data patterns and make decisions that are more efficient than manual control. Autonomous vehicles and drones exemplify how AI-infused automation is steadily changing logistics, transport, and delivery systems, thereby highlighting the necessity of these innovations in future developments.

The Rise of the Staefa Control System: A Game Changer

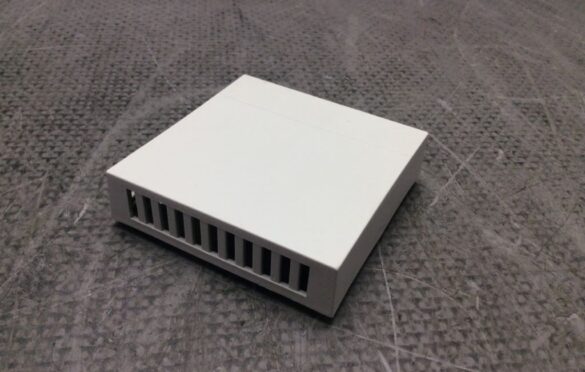

The Staefa Control System emerged as a significant player in the field of automation, particularly for building management and environmental control. Developed by Staefa Control System AG, a company known for innovative building technologies, it represents a strategic blend of hardware and software, transforming how facilities manage energy consumption, HVAC systems, lighting, and security. What sets Staefa apart is its ability to integrate various subsystems into a singular, cohesive unit. This integration allows for greater operational efficiency, as the system can be monitored and controlled from a centralized platform. It supports a variety of protocols and standards, ensuring compatibility with numerous devices and existing infrastructures. Moreover, Staefa offers data analytics capabilities that provide important insights into energy usage and system performance. This analytical strength enables facility managers to identify inefficiencies, predict maintenance needs, and enhance overall sustainability efforts. The rise of the Staefa Control System is not just about its technical prowess; it symbolizes a broader shift towards intelligent building systems that prioritize energy conservation, operational efficiency, and user comfort.

Understanding the Staefa Control System: What Makes It Unique?

A Deep Dive into the Technology Behind Staefa

At its core, the Staefa Control System functions through a combination of advanced control algorithms, a modular hardware architecture, and user-friendly software interfaces. The system employs a distributed control approach, allowing various controllers throughout a facility to communicate while retaining some level of autonomy. This architecture not only streamlines processes but also enhances system reliability by reducing the risk of a single point of failure. The heart of Staefa’s technology lies in its ability to deploy real-time monitoring and control actions. By leveraging advanced sensors and actuators, the system continuously collects data on environmental conditions, energy consumption, and equipment performance. This feedback loop is crucial for making real-time adjustments to optimize energy use, ensuring that heating, cooling, and lighting are delivered according to actual requirements rather than pre-set schedules, thereby highlighting an intelligent adaptability. Moreover, Staefa’s software platform provides comprehensive visualization tools that enable users to analyze data effectively. Trends can be spotted more readily, empowering managers to make informed decisions. With the integration of big data analytics, Staefa allows for predictive maintenance, improving equipment reliability and extending the lifespan of critical systems.

User-Friendly Interfaces: Simplifying Complex Processes

One of the standout features of the Staefa Control System is its emphasis on user-friendly interfaces that simplify complex monitoring and control tasks. A well-designed user interface (UI) is critical for operators and facility managers, as it provides them with immediate access to vital information and control functionalities without overwhelming them with technical jargon. Staefa integrates intuitive dashboards that visualize data in real-time, allowing users to track key performance indicators (KPIs) instantly. These dashboards provide insights such as energy consumption trends, equipment operation status, and alerts for maintenance needs, all tailored to the roles of specific users. Furthermore, customization options allow organizations to adapt their interface to meet specific requirements, ensuring that team members can focus on what matters most to their operations. Moreover, mobile support on various devices equips users with access to the Staefa system from anywhere. This mobility is particularly valuable for facility managers who may need to respond to issues on-site quickly. With alerts and control at their fingertips, operational efficiency can be significantly enhanced, resulting in reduced downtime and improved facility management.

Integration with IoT: The Future of Smart Buildings

The integration of IoT technology with the Staefa Control System marks a pivotal development in creating truly smart buildings. IoT enables disparate devices and systems to connect, communicate, and collaborate, creating networks that improve performance through shared data and insights. Staefa seamlessly integrates with IoT devices, allowing organizations to utilize a wide range of smart sensors, HVAC systems, and energy management tools. Through IoT integration, the Staefa system can provide granular visibility into building performance. For example, detailed analysis of occupancy patterns and environmental conditions can inform smarter energy management practices, such as adjusting HVAC settings based on actual occupancy rather than assumptions. This precision reduces energy waste, significantly contributing to sustainability goals while also decreasing overall operational costs. Furthermore, with cloud connectivity, the Staefa Control System enhances data accessibility and analyses capabilities. Users can tap into data analytics services that apply machine learning algorithms to optimize building performance continually. The future of smart buildings is inherently tied to innovations like the Staefa system, which leverages IoT data to create occupants’ environments, reduce energy consumption, and enhance building efficiency dramatically.

Real-World Applications: Transforming Industries with Staefa

Energy Management: Reducing Costs and Environmental Impact

The Staefa Control System plays a monumental role in energy management across various industries, driving substantial cost savings while also fostering eco-friendly practices. By providing an integrated platform for monitoring and controlling energy systems, the Staefa system empowers organizations to achieve their sustainability targets. Many commercial buildings, for example, face challenges related to inefficient energy use, which often leads to excessive utility bills and a significant carbon footprint. The Staefa system addresses these challenges through its advanced monitoring capabilities, which provide real-time insights into energy consumption. By identifying trends and inefficiencies, actionable strategies can be developed to reduce energy use without sacrificing comfort or productivity. Moreover, in sectors such as manufacturing and hospitality, where energy can account for a large portion of operational expenses, the Staefa system can optimize processes through predictive analytics. By forecasting energy use based on historical patterns, managers can schedule machinery operations during off-peak hours to take advantage of lower energy rates. These adjustments not only enable cost savings but significantly reduce the environmental impact, aligning with organizational sustainability goals.

Building Automation: Enhancing Comfort and Efficiency

In the realm of building automation, the Staefa Control System stands out in enhancing both comfort and operational efficiency. The comprehensive monitoring and control capabilities ensure that facilities can respond effectively to changing conditions, thereby maintaining optimal indoor environments for occupants. For instance, by utilizing sensor data from various sources, the Staefa system can adjust lighting and HVAC systems dynamically based on preferences or occupancy levels. In offices, automatic lighting systems can significantly reduce energy consumption during hours when natural light is sufficient, contributing to cost savings and an enhanced working environment. Similarly, in educational facilities, the Staefa system can adapt heating and cooling based on class schedules to ensure a comfortable learning atmosphere. Furthermore, building automation extends beyond tenant comfort to include robust security management. The Staefa Control System offers integrative capabilities with security systems, enabling seamless coordination between access controls and environmental systems. For example, in the event of an alarm trigger, the system can instantly initiate lockdown procedures while also preparing the building’s systems to ensure occupants’ safety. Through these multi-faceted enhancements, the Staefa System establishes itself as a cornerstone of effective building automation.

Case Studies: Success Stories from Around the Globe

The impact of the Staefa Control System across various countries and sectors exemplifies its value as a transformative automation solution. Numerous case studies have documented the successes realized through its implementation. For example, a leading global retail chain deployed the Staefa system across several of its locations. Through the system’s analytics, the company identified key trends in energy usage and potential cost-saving measures. By optimizing HVAC controls across stores in response to occupancy patterns, they achieved an unprecedented 25% reduction in energy costs within the first year, demonstrating a significant win for both operations and sustainability. In another notable case, an international university implemented the Staefa Control System to modernize its aging campus buildings. By utilizing the system’s data analytics capabilities, the university significantly enhanced energy efficiency, reducing its overall carbon footprint by over 30% within two years. Additionally, students and faculty benefited from improved indoor climates that promoted productivity and comfort. These success stories illustrate how organizations worldwide leverage the Staefa Control System to elevate their operational capabilities, reduce costs, and embrace sustainability—inspiring countless others to reimagine their approaches to automation.

The Future Ahead: What’s Next for Automation and Staefa?

Trends to Watch: AI and Machine Learning in Automation

As technology continues to evolve, the future of automation remains promising, especially with advancements in artificial intelligence (AI) and machine learning. The integration of these technologies into control systems like Staefa will define the next era of intelligent automation. AI has the potential to revolutionize how systems analyze vast amounts of data, enabling predictive capabilities that can anticipate needs and optimize performance in real time. For instance, AI algorithms can mine historical data to forecast equipment failures before they occur, reducing downtime and maintenance costs, a critical feature for facilities with critical uptime requirements. Moreover, machine learning can enhance user experiences by personalizing settings based on individual preferences. For example, integrating AI into the Staefa Control System could lead to adaptive environments that learn from user interactions, fine-tuning heating, cooling, and lighting to create ideal conditions. This level of adaptability not only enhances occupant satisfaction but also drives energy efficiency, aligning with global sustainability initiatives. As AI and machine learning technologies become more sophisticated, their integration into automation systems such as Staefa will inevitably yield improved operational intelligence, efficiency, and user experience, catapulting industries into a new era of automation.

The Role of Sustainability in Future Automation Solutions

With increasing emphasis on climate change and environmental conservation, sustainability will continue to shape the future of automation solutions. Businesses are under growing pressure to minimize their environmental footprint, and advanced automation systems will be key to achieving these objectives. The Staefa Control System exemplifies how intelligent building management can directly support sustainability initiatives. Future iterations of the system will likely incorporate even more advanced energy management features, allowing buildings to harness renewable energy sources more effectively. For example, buildings could employ energy storage systems that can store solar energy generated during the day, optimizing energy utilization based on demand spikes during peak hours. Moreover, as regulatory frameworks become more stringent regarding emissions standards, automation solutions will need to evolve not just to comply but to lead in sustainability. Systems like Staefa will play a pivotal role in helping businesses meet these regulations by providing clear data and accountability for environmental performance, allowing firms to transparently convey their sustainability efforts to stakeholders. Ultimately, the integration of sustainability into automation tactics represents a crucial step toward creating efficient, future-proof operations, ensuring that organizations thrive in a world where water and energy conservation are paramount.

Preparing for the Future: Skills and Innovations Needed

As the landscape of automation continues to transform, the skills required for the workforce must adapt to meet evolving demands. A comprehensive understanding of both technology and data analytics will be vital for professionals in the automation field. The rise of intelligent systems necessitates a workforce that is not only technologically adept but also skilled in interpreting and deriving actionable insights from complex data. Additionally, as automation becomes more integrated into everyday operations, employees will need to cultivate strong problem-solving skills that allow them to address unique challenges. Understanding the underlying principles of AI and machine learning, as well as emerging trends in Industry 4.0, will be essential for those looking to thrive within automated environments. Moreover, organizations must commit to continuous learning and development to keep pace with technological advancements. By investing in training programs that foster innovation and upskilling, industries can ensure that they are prepared for the future landscape of automation, ready to harness the full potential of solutions such as the Staefa Control System. In conclusion, the evolving narrative of automation, underscored by innovative systems like the Staefa Control System, depicts a future replete with opportunities for enhanced efficiency, sustainability, and user comfort. By embracing these advancements, industries can chart a course toward intelligent automation that serves not only operational objectives but societal and environmental goals as well.